Power steering repair Auckland involves the professional diagnosis and restoration of your vehicle’s hydraulic or electric steering system to eliminate whining noises, fluid leaks, and stiff handling. To ensure safety and pass Warrant of Fitness (WoF) checks, qualified mechanics inspect the pump, rack, hoses, and belt tension before performing necessary replacements.

Understanding Power Steering Systems

The modern automobile is a marvel of engineering, and few components are as critical to the driving experience as the power steering system. Whether you are navigating the tight urban streets of the CBD or cruising on the motorway, the ability to steer your vehicle with minimal effort is something most drivers take for granted—until it fails. When seeking power steering repair Auckland services, it is essential to understand that this system is the bridge between the driver’s input and the vehicle’s directional control.

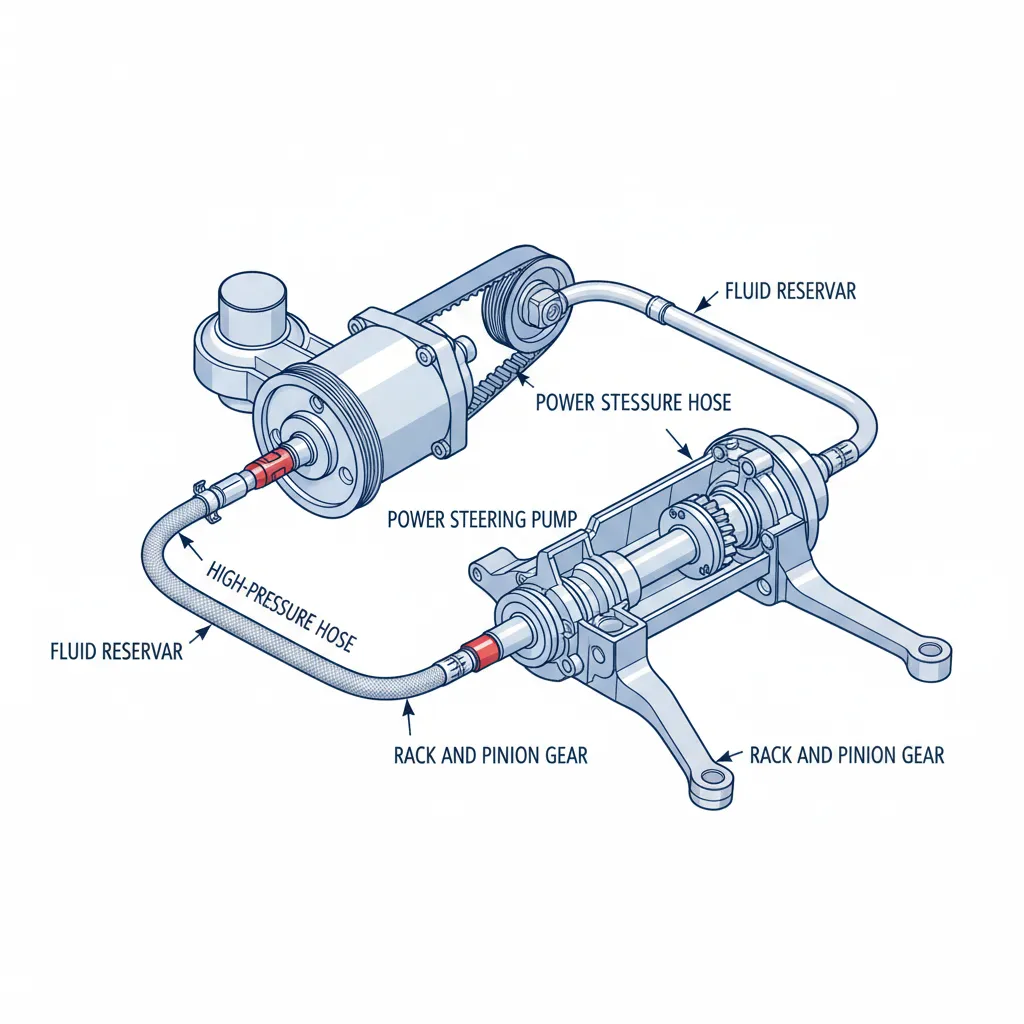

There are generally two types of systems found in vehicles on New Zealand roads today: Hydraulic Power Steering (HPS) and Electric Power Steering (EPS). Hydraulic systems rely on a pump driven by the engine’s belt to pressurize fluid, which then assists the movement of the rack and pinion. Electric systems, which are becoming standard in newer models, utilize an electric motor and sensors to provide assistance, eliminating the need for hydraulic fluid entirely.

Regardless of the type, a failure in this system does not just mean a workout for your arms; it represents a significant safety hazard. A sudden loss of power assist during a turn can lead to understeering and potential accidents. Therefore, recognizing the early signs of wear and tear is paramount for every vehicle owner.

Critical Symptoms: Whining Noises When Turning

One of the most immediate and alarming indicators that your vehicle requires attention is the presence of audible distress signals. Whining noises when turning are not normal and usually indicate that the power steering pump is struggling. This sound is often described as a high-pitched groan or a buzz that intensifies as you turn the steering wheel further toward the lock position.

The Mechanics of the Whine

This noise is typically caused by cavitation. Cavitation occurs when air bubbles form within the hydraulic fluid and then collapse under pressure. This can happen for several reasons:

- Low Fluid Levels: If the reservoir is low, the pump sucks in air along with the fluid. The mixture of air and fluid is compressible, unlike pure fluid, causing the pump to vibrate and whine.

- Old or Degraded Fluid: Over time, power steering fluid can absorb moisture and lose its lubricating properties. This increases friction within the pump vanes, leading to noise.

- Blocked Reservoir Filter: Many reservoirs have a fine mesh screen at the bottom. If this becomes clogged with debris, the pump starves for fluid, creating a vacuum that results in a loud whining sound.

If you hear these noises, immediate inspection is required. Continuing to drive with a whining pump can cause metal shavings to circulate through the system, effectively destroying the steering rack and requiring a complete system overhaul rather than a simple repair.

Diagnosing Fluid Leaks and Top-Up Dangers

Fluid leaks and top-ups are a common scenario for many car owners, but treating a leak by simply adding more fluid is a temporary and dangerous fix. Power steering fluid is typically red or pink (though it can turn brown/black when burnt) and has a distinct smell. Finding a puddle of this fluid under your car is a clear sign that the integrity of the hydraulic system has been compromised.

Common Leak Locations

Leaks can originate from several points in the high-pressure system:

- Pressure Hoses: These hoses carry fluid at extremely high pressures (often exceeding 1,000 PSI) from the pump to the rack. The rubber can degrade, crack, or separate from the metal crimps over time.

- Return Lines: These carry fluid back to the reservoir at lower pressure. While less prone to bursting, they are subject to rotting and clamp failure.

- Steering Rack Seals: The seals at the ends of the steering rack (hidden inside the rubber bellows or “boots”) can fail. If you squeeze the rubber boot and it feels squishy or fluid drips out, the internal seals are blown.

Ignoring a leak leads to pump failure due to fluid starvation. Furthermore, power steering fluid is flammable. A leak spraying onto a hot exhaust manifold is a significant fire risk. For reliable power steering solutions, it is crucial to address the source of the leak, not just the symptom.

Pump Failure Symptoms and Replacement

The power steering pump is the heart of a hydraulic system. When it begins to fail, the symptoms are often progressive. Apart from the whining noises mentioned earlier, pump failure symptoms manifest physically in the handling of the vehicle.

Intermittent Power Assist

You may notice that the steering works fine at highway speeds but becomes incredibly heavy when you are trying to park. This “variable assist” failure often indicates that the pump cannot generate enough pressure at low RPMs (revolutions per minute). Conversely, the steering might feel jerky or notched, as if it is slipping, which suggests the internal vanes of the pump are worn out.

The Replacement Process

Replacing a power steering pump is a precise task. It involves:

- Draining the old, contaminated fluid.

- Removing the drive belt and the high-pressure lines.

- Installing the new pump and torqueing bolts to manufacturer specifications.

- Bleeding the System: This is the most critical step. After installation, the system must be bled to remove all air pockets. Failure to do so will result in immediate noise and potential damage to the new unit.

The Importance of Belt Tension Checks

In hydraulic systems, the pump is driven by the engine via a belt—often the serpentine belt that also drives the alternator and air conditioning compressor. Belt tension checks are a vital part of diagnosing steering issues.

If a belt is loose, it will slip on the pump pulley, especially when the demand on the pump is highest (such as turning the wheel while stopped). This slipping produces a loud, piercing squeal. However, the issue isn’t always the belt itself; it can often be a failing automatic tensioner.

A snapped belt results in an immediate and total loss of power steering assist. While the car can still be steered manually, the effort required is immense, which can be terrifying if it happens at speed or during a sharp corner. Routine maintenance should always include inspecting the condition of the drive belt for cracks, fraying, or glazing, and ensuring the tensioner is applying the correct amount of force.

Rack and Pinion Issues: The Hidden Culprit

While pumps and hoses are common failure points, the steering rack (rack and pinion) is the most expensive component to repair. The rack converts the rotational motion of the steering wheel into the linear motion required to turn the wheels.

“Morning Sickness”

A classic symptom of rack failure is known as “morning sickness.” This occurs when the steering feels incredibly stiff when you first start the car on a cold morning but becomes easier as the engine warms up. This is caused by internal seals within the rack hardening and shrinking in the cold, allowing fluid to bypass the piston. As the fluid warms and expands, the seals soften, and assist returns.

Dead Spots and Wandering

Wear in the center teeth of the rack can cause a “dead spot” where the steering wheel can be turned slightly without moving the tires. This leads to the vehicle wandering on the road, requiring constant correction to stay in the lane. This is a severe safety issue and a guaranteed failure for any vehicle inspection.

Electric Power Steering (EPS) Diagnostics

Modern vehicles in Auckland are increasingly equipped with Electric Power Steering (EPS). These systems do not use fluid, pumps, or hoses. Instead, an electric motor mounted on the steering column or the rack provides the assist.

Common EPS Failures:

- Overheating: Continuous lock-to-lock turning (like parallel parking repeatedly) can cause the motor to overheat and temporarily shut down to protect itself.

- Sensor Failure: Torque and position sensors tell the computer how much assist to apply. If these fail, the steering warning light will illuminate on the dashboard, and the system may enter a “limp mode” with reduced or no assist.

- Calibration Issues: After a wheel alignment or battery replacement, the steering angle sensor may need recalibration using a specialized scan tool.

Repairing EPS systems generally requires advanced diagnostic computers and often involves replacing electronic modules rather than mechanical parts.

Passing Your WoF: Auckland Compliance Standards

In New Zealand, the Warrant of Fitness (WoF) is a mandatory regular check to ensure your vehicle meets required safety standards. The NZ Transport Agency (Waka Kotahi) sets strict guidelines regarding steering systems.

To pass a WoF in Auckland, your steering system must demonstrate:

- No Leaks: Any dripping fluid from the steering rack or hoses is a fail.

- Secure Mounting: The steering rack must be securely mounted to the chassis with no excessive play in the bushes.

- Smooth Operation: The steering must turn smoothly from lock to lock without jamming or roughness.

- Condition of Boots: The rubber dust boots on the rack ends must be intact. Split boots allow dirt to enter and destroy the seals, leading to a fail.

Seeking professional power steering repair in Auckland before your WoF inspection can save you the hassle of a failed result and a re-inspection fee.

Maintenance Tips to Extend Component Lifespan

Preventative maintenance is always more cost-effective than reactive repair. To extend the life of your power steering system, consider the following best practices:

- Regular Fluid Flushes: Power steering fluid should be flushed and replaced every 80,000 to 100,000 kilometers. Fresh fluid contains additives that condition seals and prevent corrosion.

- Inspect Dust Boots: visually check the rubber boots on your steering rack during oil changes. If they are cracked, replace them immediately to protect the expensive rack.

- Avoid “Lock-Holding”: When turning the steering wheel to the absolute limit (lock), back it off slightly. Holding it hard against the stop puts maximum strain on the pump and increases fluid temperature rapidly.

- Listen to Your Car: Do not ignore the early warning signs of whining or squealing. Addressing a loose belt or a minor leak today can prevent a catastrophic pump failure tomorrow.

Whether you are driving an older hydraulic vehicle or a modern electric model, the steering system is vital for your safety. If you suspect any issues, contact a specialist in power steering repair Auckland immediately to diagnose the fault and restore your vehicle’s handling.

People Also Ask

How much does power steering repair cost in Auckland?

The cost varies significantly depending on the issue. A simple hose replacement or fluid flush might cost between $150 and $300 NZD. However, replacing a power steering pump can range from $400 to $900, while a complete rack and pinion replacement can cost upwards of $1,200 to $2,500 depending on the vehicle make and model.

Can I drive my car with a power steering leak?

It is not recommended. While you can physically drive the car, a leak will eventually lead to a dry pump, causing it to seize and potentially snap the drive belt. This could leave you stranded or cause damage to other engine components. Furthermore, leaking fluid is a fire hazard.

How do I know if it’s the pump or the rack?

Generally, a failing pump causes whining noises and intermittent loss of assist, particularly at low speeds. A failing rack often causes ‘morning sickness’ (stiff steering when cold), wandering on the road, or fluid leaking specifically from the rubber boots (bellows) near the wheels.

What is the difference between hydraulic and electric power steering?

Hydraulic power steering uses a fluid-filled system pressurized by an engine-driven pump to assist steering. Electric Power Steering (EPS) uses an electric motor and sensors to provide assist, eliminating the need for fluid, pumps, and hoses, which improves fuel efficiency and reduces maintenance.

Why is my power steering making a whining noise?

A whining noise usually indicates air in the system, low fluid levels, or a failing pump. The noise is caused by cavitation, where air bubbles collapse under pressure, or by the pump components grinding due to lack of lubrication.

Does power steering fluid need to be changed?

Yes, power steering fluid degrades over time due to heat and contamination. Most manufacturers recommend flushing the system every 80,000 to 100,000 kilometers to prevent sludge buildup and protect the seals and pump from wear.