The average brake pad replacement cost in Auckland typically ranges between $180 and $450 NZD per axle, depending heavily on your vehicle’s make, the type of friction material selected, and whether rotor machining is required. Mobile brake services generally offer competitive pricing by reducing workshop overheads while providing the convenience of on-site repairs at your home or workplace, servicing areas across Auckland, including Mt Wellington and Central Auckland.

Understanding Brake Pad Replacement Costs in Auckland

When searching for “brake pad replacement cost Auckland,” it is essential to understand that the price tag is rarely a flat rate. The automotive service industry in New Zealand varies significantly based on several technical and logistical factors. While the convenience of a mobile mechanic often translates to time savings, the monetary cost is influenced by the specific requirements of your vehicle.

The primary driver of cost is the vehicle origin. Auckland’s roads are dominated by a mix of Japanese imports (Toyota, Mazda, Nissan) and European vehicles (Volkswagen, BMW, Audi). Generally, Japanese vehicles utilize standard braking systems that are cost-effective to service, with pad sets often costing between $80 and $150. Conversely, European vehicles frequently require specialized sensors, softer compound pads for higher performance, and sometimes single-use hardware that must be replaced, pushing parts costs significantly higher.

Labor is the second component. Traditional workshops have high overheads (rent, electricity, administration) which are factored into their hourly rate. Mobile mechanics, operating out of fully equipped vans, often have lower overheads, allowing for competitive pricing for a range of services, including Starter Motor Problems Diagnosis & Repair Auckland. However, the true value lies in the opportunity cost; you are not losing two hours of your day dropping off and picking up a car. In Auckland’s traffic, this convenience is a tangible financial benefit.

Critical Warning Signs: Squeaky Brakes and Wear Indicators

Brake pads are a consumable item, designed to wear down sacrificially to stop your vehicle. Ignoring the signs of wear can lead to metal-on-metal contact, which destroys rotors and can cause catastrophic brake failure. Recognizing the auditory and tactile signals of brake wear is crucial for safety.

Auditory Signals

The most common sign is a high-pitched squealing noise. This is often designed intentionally. Many brake pads feature a small metal tab called a mechanical wear indicator. When the pad material wears down to a safe minimum (usually 2-3mm), this tab contacts the rotor, creating a piercing squeal to alert the driver. If this sound changes to a deep, guttural grinding noise, the pads are completely gone, and the metal backing plate is cutting into the rotor. At this stage, costs escalate as rotors will almost certainly need replacement.

Tactile and Visual Indicators

Modern vehicles, particularly European models common in Auckland, utilize electronic wear sensors. These are embedded in the pad and trigger a dashboard warning light when the circuit is broken by contact with the rotor. Beyond lights, pay attention to the pedal feel. A spongy pedal can indicate air in the lines or fluid issues, while a vibrating pedal during braking usually suggests warped rotors (runout).

Ceramic vs. Semi-Metallic: Choosing the Right Friction Material

When booking a mobile brake replacement, you may be offered a choice of pad materials. Understanding the difference between ceramic and semi-metallic pads is vital for matching performance to your driving style.

Semi-Metallic Brake Pads

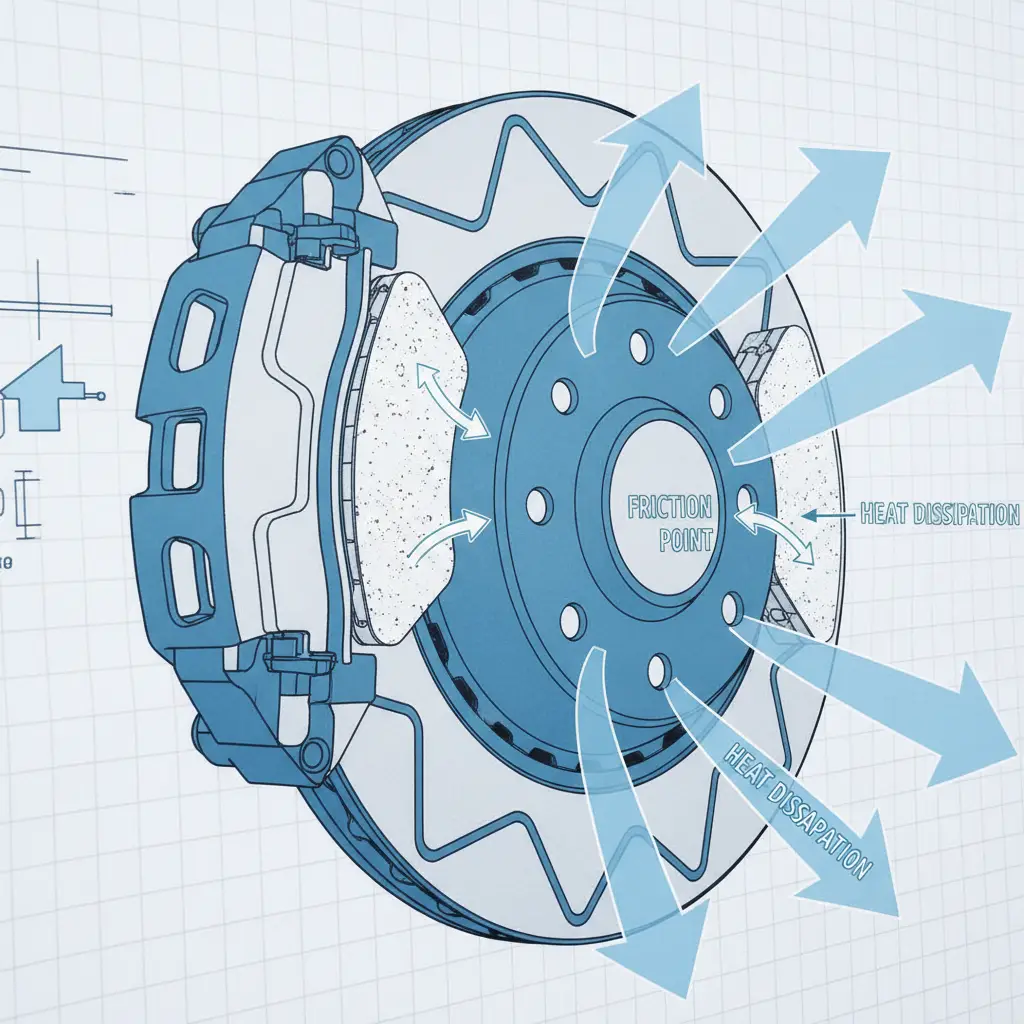

Semi-metallic pads are composed of 30% to 70% metal (copper, iron, steel) combined with graphite lubricants and other fillers. They are the standard for many vehicles because of their robust stopping power and excellent heat dissipation.

- Pros: Superior braking bite, especially in cold weather; generally cheaper; excellent heat transfer.

- Cons: They generate significant black brake dust which can ruin the look of alloy wheels; they are noisier than ceramics; they are more abrasive, leading to faster rotor wear.

Ceramic Brake Pads

Ceramic pads are made from a dense ceramic compound mixed with copper fibers. They represent a more modern approach to braking technology and are increasingly popular for daily drivers in urban environments like Auckland.

- Pros: Extremely quiet operation; they produce a light-colored dust that doesn’t stick to wheels; longer lifespan for both the pad and the rotor; stable performance across a wide range of temperatures.

- Cons: More expensive to purchase; less “cold bite” than semi-metallics (they need a little heat to work optimally); not suitable for heavy towing or track use.

For the average Auckland commuter dealing with stop-start traffic on the Southern Motorway, ceramic pads are often the superior choice due to their low dust and noise properties.

The Mobile Advantage: On-Site Replacement Process Explained

Many vehicle owners are skeptical about how a complex mechanical job can be performed in a driveway. However, mobile brake replacement is a streamlined, safe, and highly effective process. Here is what you can expect from a professional mobile service.

1. Site Safety Assessment: The mechanic first ensures the ground is level and stable. While a garage is preferred, a flat driveway is perfectly adequate. They will chock the wheels to prevent rolling.

2. Disassembly and Inspection: The vehicle is jacked up, and the wheel is removed. The mechanic removes the caliper guide pins and lifts the caliper. This is the critical inspection phase. They check the caliper piston for seizing, the slide pins for lubrication, and the brake lines for cracks or leaks. According to safety authorities like the NZ Transport Agency (Waka Kotahi), the condition of hoses and connections is just as vital for a Warrant of Fitness (WOF) as the pad thickness.

3. Hardware Replacement: It is not enough to just swap the pads. A quality service involves cleaning the caliper bracket with a wire brush to remove rust buildup. New stainless steel abutment clips (hardware) should be installed to ensure the pads slide freely. The slide pins are cleaned and re-greased with high-temperature silicone lubricant.

4. Installation and Torquing: The piston is compressed back into the caliper (requiring a wind-back tool for many rear brakes with integrated parking brakes). New pads are installed, and the caliper is bolted back on. Crucially, a professional will use a torque wrench to tighten lug nuts to the manufacturer’s specification, preventing warped rotors.

Rotors and Calipers: Beyond Just Pads

A common misconception is that you can change pads indefinitely without addressing the rotors (discs). Rotors wear down and can develop grooves or thickness variations. When you install flat, new pads onto a grooved rotor, you reduce the contact patch significantly, reducing braking efficiency.

In Auckland, mobile mechanics generally have two approaches to rotors: replacement or assessment for machining. While some workshops offer on-car machining, mobile mechanics usually recommend replacement if the rotors are near their minimum thickness. Replacement is often more cost-effective in the long run than machining, as modern rotors have become relatively affordable. If a rotor is too thin, it cannot dissipate heat effectively, leading to brake fade on steep descents, such as the Bombay Hills.

Bedding In: Essential Post-Installation Care

Once the mechanic leaves, the job is not 100% complete. You must “bed in” or “burnish” the new brakes. This process transfers a thin layer of friction material from the pad to the rotor, establishing a mating surface that ensures maximum stopping power and quiet operation.

The general procedure (though you should follow the specific manufacturer instructions) involves:

- Accelerate to about 50 km/h.

- Apply moderate brake pressure to slow down to 10 km/h (do not come to a complete stop).

- Repeat this process 8 to 10 times.

- Drive for a few minutes without braking heavily to allow the system to cool.

Failure to bed in brakes can result in “glazing,” where the resin in the pad crystallizes, leading to poor braking performance and persistent squeaking. Proper bedding ensures your investment in new brakes lasts as long as possible.

Frequently Asked Questions

How much does it cost to replace brake pads in Auckland?

In Auckland, brake pad replacement generally costs between $180 and $450 NZD per axle. This price varies based on vehicle make (European cars are typically more expensive), the type of pads chosen (ceramic vs. semi-metallic), and whether mobile service or a workshop is used.

Is it cheaper to replace your own brake pads?

Yes, DIY replacement is cheaper as you save on labor costs, paying only for parts ($50-$150). However, without proper tools and knowledge, you risk safety issues, improper installation, and potential WOF failure. Mobile services offer a balance of convenience and professional safety assurance.

Do I need to replace rotors every time I change pads?

Not necessarily. Rotors usually last through two sets of brake pads. However, they must be measured for thickness and checked for warping or deep grooves. If they are below the manufacturer’s minimum thickness specification, they must be replaced for safety.

How long does a mobile brake replacement take?

A standard mobile brake pad replacement typically takes 45 to 60 minutes per axle. If rotors need to be replaced or if there are seized bolts due to rust, the process may take longer. The benefit is that this happens at your location, saving you travel time.

Are ceramic brake pads better than semi-metallic?

Ceramic pads are generally considered better for daily urban driving because they produce less dust, are quieter, and last longer. However, semi-metallic pads offer a stronger initial ‘bite’ and are better suited for heavy-duty towing or high-performance driving.

Will mobile brake replacement affect my warranty?

Generally, no. As long as the mobile mechanic is a qualified professional and uses parts that meet or exceed OEM specifications, your vehicle warranty remains intact. Always ensure the service provider is reputable and provides a receipt for the work done.